WE ARE EXPERTS in the research and design of high-tech solutions in hardness testers since 1954. More than 60 years of hard work. AFFRI workers have faced a wide variety of challenges and are experienced in every field of application. The level of knowledge now achieved by AFFRI makes us the best solution. Find here all range of AFFRI Hardness Testers: from Rockwell to Portable hardness testing machines.

CASE STUDIES

Take a look at the many fields of application. AFFRI has the answer to your needs.

ARE YOU LOOKING FOR UTM?

Material testing machines with absolute measurement on the extension. Definition of 0.001 mm and different strain gauge modes: automatic, and optical systems. Extraordinary reactive measurements and a high-level sensitivity of 1ms (millisecond) and 100,000 divisions.

ARE YOU LOOKING FOR NIKON MICROSCOPES ?

Now AFFRI Inc. is official distributor of NIKON in USA, South America, Canada, Europe and Asia for industrial microscopes. Come here and discover our products.

LATEST VIDEOS

The AFFRI SYSTEM

MRS Serie

WIKI JS

RSDMAG

LD3000AX

LD750 XY

HARDNESS TESTING

BASIC KNOWLEDGE

If you are looking for what is a hardness test and how you can test the hardness of your product, you can read the explanation below. There are three principal hardness test methods: Rockwell, Brinell, and Vickers. Select one of the below-mentioned test methods for more details. Discover more about AFFRI hardness testers knowing more about hardness testing methods.

For any further information on our products range, you’re welcome to contact us.

FAQ

FREQUENTLY ASKED QUESTIONS

The choice of the hardness tester type and model depends on the characteristics of the parts to test, the material and the level of accuracy required for the final hardness result. Is the measurement done for a quick hardness test on incoming material or is it done to certify the quality of the product? For which material is the hardness test needed; metals, steel, aluminum, cast iron, plastic, rubber? What are the dimensions of the part for hardness testing and what is the minimum thickness? Is the hardness test done on coatings or is it needed for core hardness? What is the frequency of hardness testing; hourly, daily or seldom?

It is not a good strategy to base the procurement of a hardness tester basing only on the hardness scale needed (Rockwell, Brinell, Vickers, Shore,). Or, hardness tester price. Of course, the purchase of the hardness tester must stay within a budget but this doesn’t mean that it is the lowest cost, solution in the long term.

If you’re looking for a hardness tester but you don’t know which one to choose, we invite you, to contact us, we will guide you to the right choice.

In addition, if you want to have an idea about which parameters you have to consider before selecting a hardness tester, have a look to the following survey: click here.

The hardness tester price can vary from a low-cost solution for a small amount of money, increasing depending on the level of automation. The biggest thing to consider is the volume of tests per day and the number of operators involved in the use of the instrument. The smaller the number is, the cheaper the hardness tester can be. On the other side, in case of massive hardness testing volumes, it is better to purchase a fully automatic hardness tester which saves operator time and therefore money.

The hardness tester price depends also on the testing capabilities: the number of calibrated scales and the possible testing load range is a large factor affecting the hardness tester cost. The budget for the purchase of the hardness tester should also consider the number of indenters needed, test blocks, and other accessories.

Affri has two productive and commercial offices. One is located in Italy since the company’s inception, based in Induno Olona. The second one is located in the United States, Illinois. These two Sales offices allow us to serve our sales and services network worldwide.

If you’re looking to buy a hardness tester, AFFRI, just contact us, we will direct you to the closest official distributor who will answer all your questions and guide you in the purchase of the right hardness tester for your needs.

For any information about products, services, or demonstrations of our hardness testers, please don’t hesitate to contact us.

The hardness tester doesn’t need a big maintenance procedure. Since it is a quality control instrument it is important to keep it clean and to use it as recommended by the hardness tester manufacturer. Once per year or two, the hardness tester has to be calibrated according to ASTM and ISO standard procedures. During the service, it is well recommended to check the mechanics, clean the sample holder and anvils, lubricate when needed and replace worn parts.

The advantage to calibrate the hardness tester through a company like AFFRI is that during the service, our technicians can repair the tester or adjust the measuring errors.

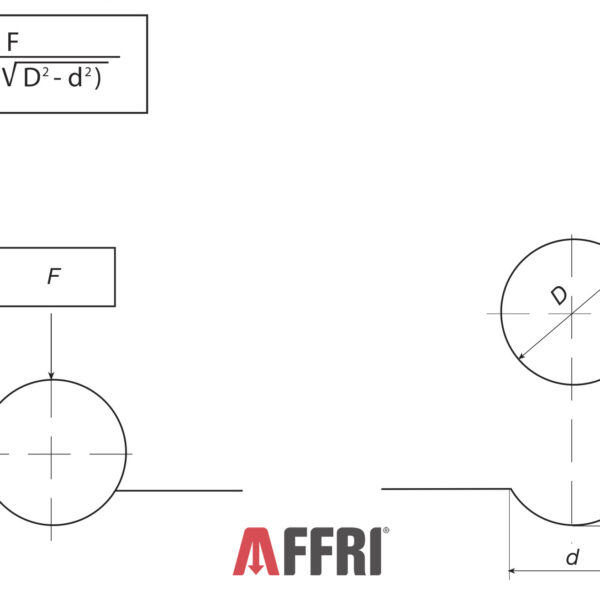

A Brinell hardness tester is an instrument suitable for testing the hardness of rough metals, steel, cast iron aluminum and it is particularly used in the industries of forgings, castings and heat treatments. The Brinell hardness testing method consists in applying a certain force over a carbide tungsten ball indenter, then reading the diameter of the impression, in order to obtain the final result. The bigger the indentation (mark left from the ball indenter on the test surface) the softer the material. Smaller the indentation the harder the material.

The Brinell hardness test uses a ball indenter (1, 2.5, 5 or 10 mm) because it allows to test a larger area, of the material and “group” together all its components. This is why, this method is used in the industries mentioned.

Here’s the AFFRI Brinell range: Brinell Hardness Testers

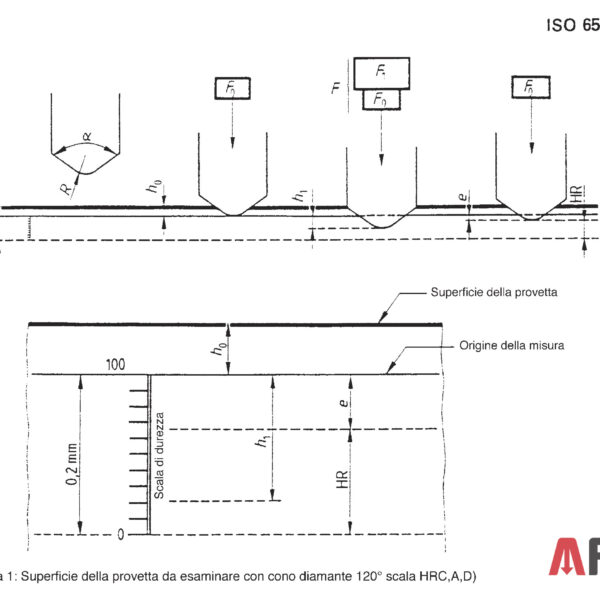

A Rockwell hardness tester is an instrument suitable for testing the hardness of steel, alloys and metals, particularly used on finished products in production departments. The Rockwell hardness testing method consists of applying a certain force over a diamond cone or carbide tungsten ball indenter and then measuring the depth of indentation to obtain the final result. The deeper the indentation the, softer the material. Thinner the indentation the, harder the material.

The Rockwell hardness test uses a diamond cone 120° or ball indenter (1/16″, 1/8″, 1/4″ or 1/2″ mm) and it is the easiest and quickest hardness test procedure.

Here’s the AFFRI Rockwell range: Rockwell Hardness Testers

A Vickers hardness tester is an instrument suitable for testing the hardness of any metal, very hard or soft, particularly used in laboratory. The Vickers hardness testing method consists of applying a certain force over a diamond pyramid 136° indenter and then reading the indentation diagonal length in order to obtain the final result. The bigger the indentation (mark left from the indenter on the test surface) the, softer the material. The smaller the indentation is, the harder the material.

The Vickers hardness test is the most accurate method where the very wide load range allows measurements on cents on millimeters areas or very thin coating layers.

Here’s the AFFRI Vickers range: Vickers Hardness Testers

Choice to be made in purchasing a portable or a stationary hardness tester is only a matter of portability. Do you have to test the hardness in production department on various samples? Buy a portable hardness tester. Do you have to test the hardness on site over very big parts? Buy a portable hardness tester. Do you have to test incoming materials directly on the shipping truck? Yes, you have to use a portable hardness tester.

A big mistake when looking for a portable unit is thinking about the hardness tester price. Hoping that a smaller instrument can be a lower cost hardness tester. Affri portable hardness testers have the same accuracy of stationary machines, embedding high technological standards into a compact hardness tester.

Here’s the AFFRI portable range: Portable Hardness Testers